Neck build process (pictures below):

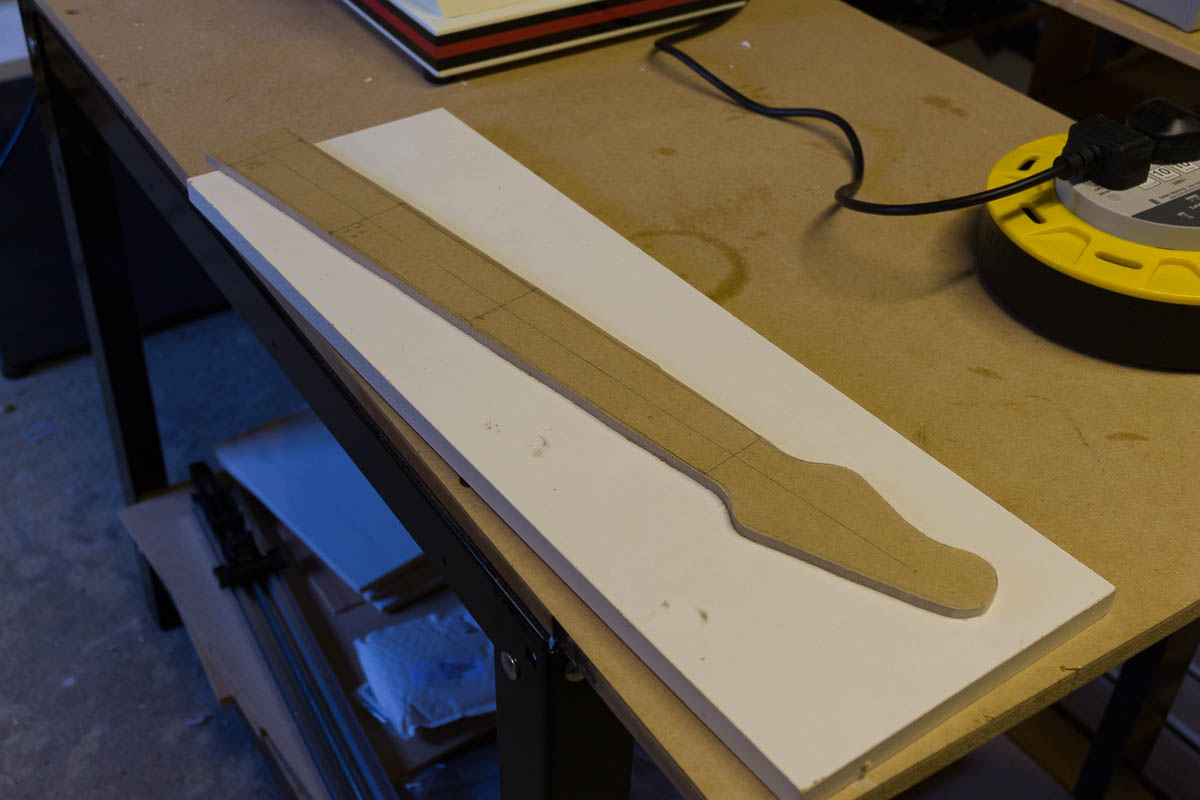

- Template made in 6mm MDF. Neck measurements came from an Excel spreadsheet (which I’ll refine over time)

- Number of frets: 21

- Neck end fret: 22 (i.e. neck finishes were the 22nd fret would be)

- Body join fret: 16

- Added 2mm to sides for sanding – however I’m still not convinced my neck calcs are correct, as it still seems narrower than expected for the string spacing at the body end.

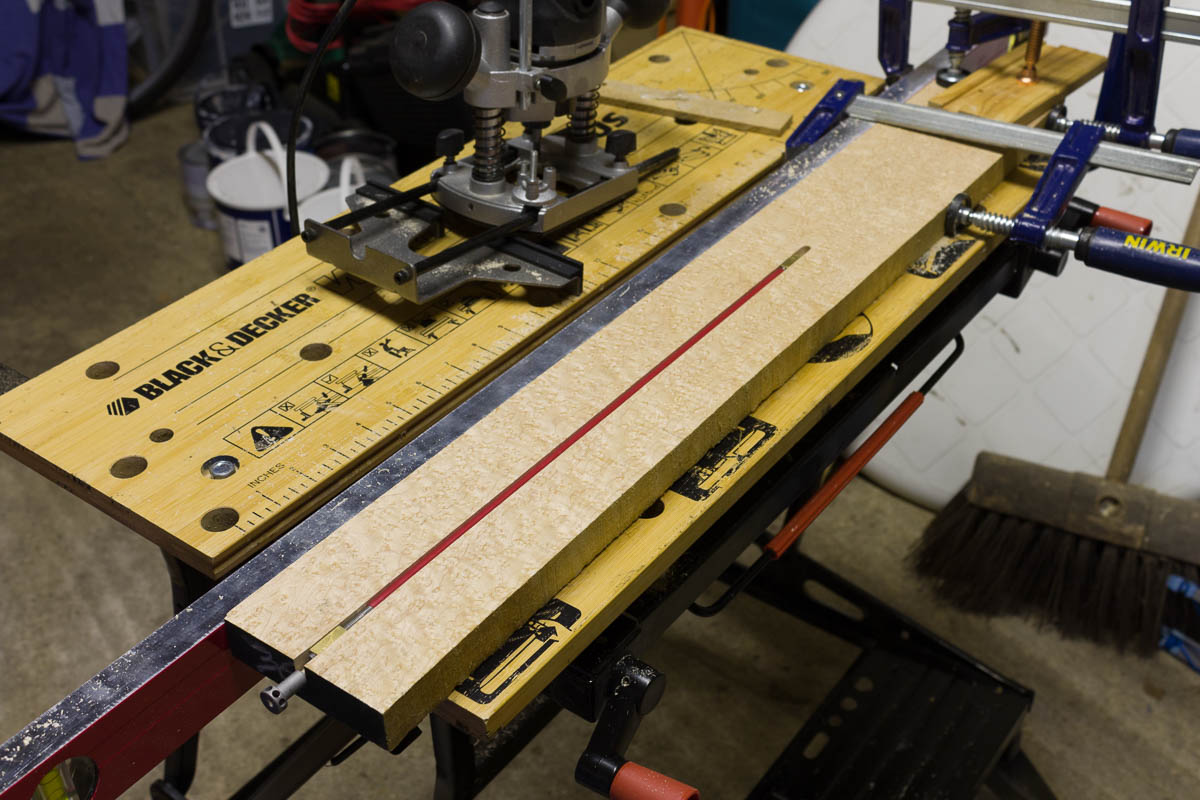

- Truss rod channel cut. This is the first neck wood I’ve worked with that hasn’t been planned square. Instead I clamped a straight edge to the side of the piece and used that as the guide for the truss rod slot (which for a Stewmac Hotrod is 5.5mm wide, 11.1mm deep and 457mm long – use the router custom bit they make!).

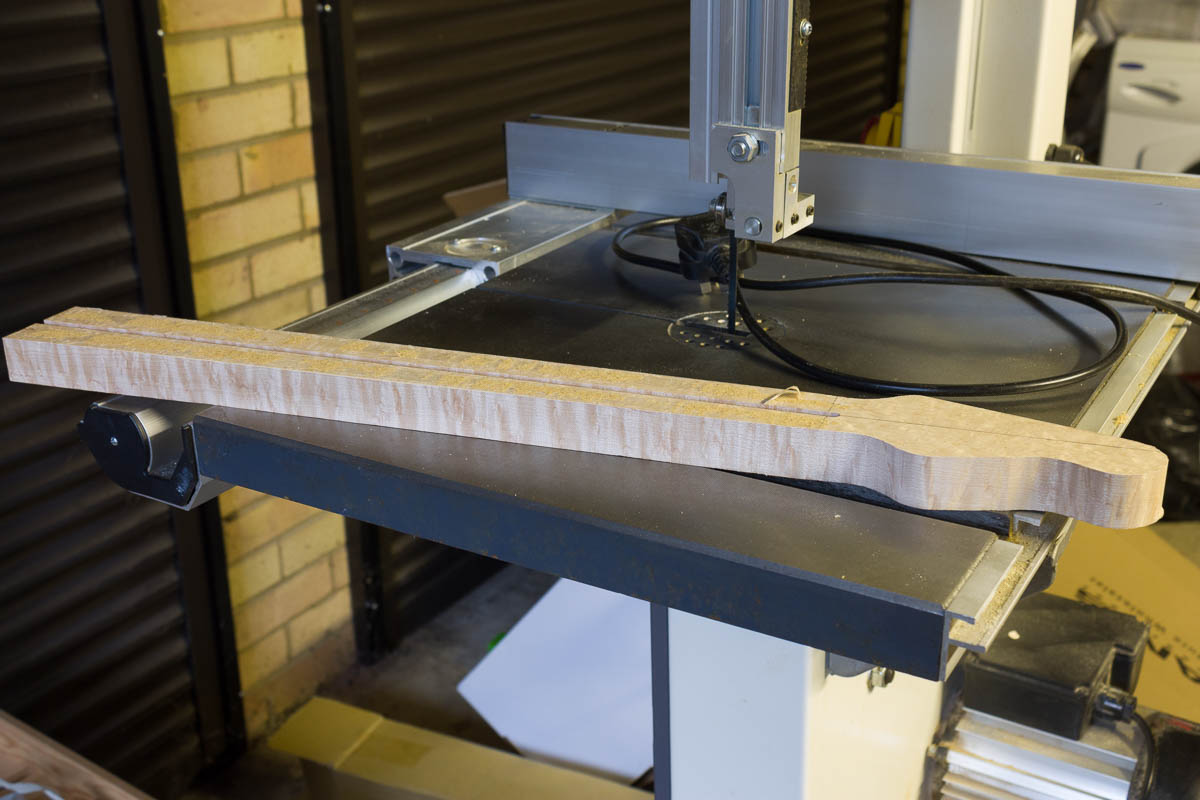

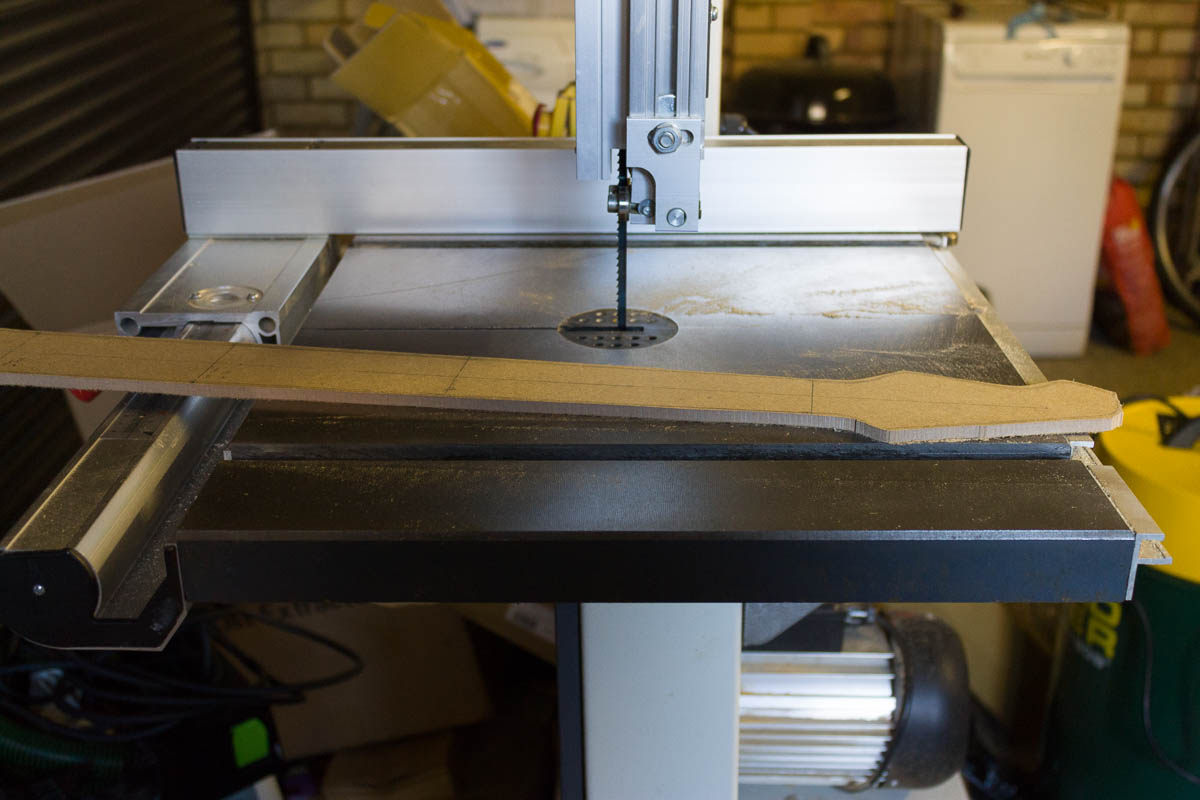

- Outline copied onto neck, rough cut on bandsaw

- Double sided sticky tape on the MDF template and copy onto neck

Birds-eye maple seems prone to tiny tear outs and I had large one around the 20th fret on the low side. Hopefully with sanding it’ll be either fully removed, or very minor. However, in the bottom picture you can start to see the amazing figuring in this piece of wood. I hope it will be worth it!